At a Glance: 3D printing strong, durable polymers is essential for parts that must endure real-world industrial conditions. Selecting the right material isn’t about finding a single “strongest” option but matching polymers to application needs. From tensile and impact strength to heat and chemical resistance, every factor shapes performance. By choosing materials based on use-case requirements, functional prototypes and end-use parts can achieve both reliability and long-term durability.

When you need to print parts that can withstand harsh industrial conditions, you’ll want to use strong 3D printing materials. But it isn’t always clear what the best choice is.

It would be nice if there were a single, universal metric that described material strength or durability, and you could simply choose the “most durable" 3D printing material for your application. However, the reality is a lot more complex:

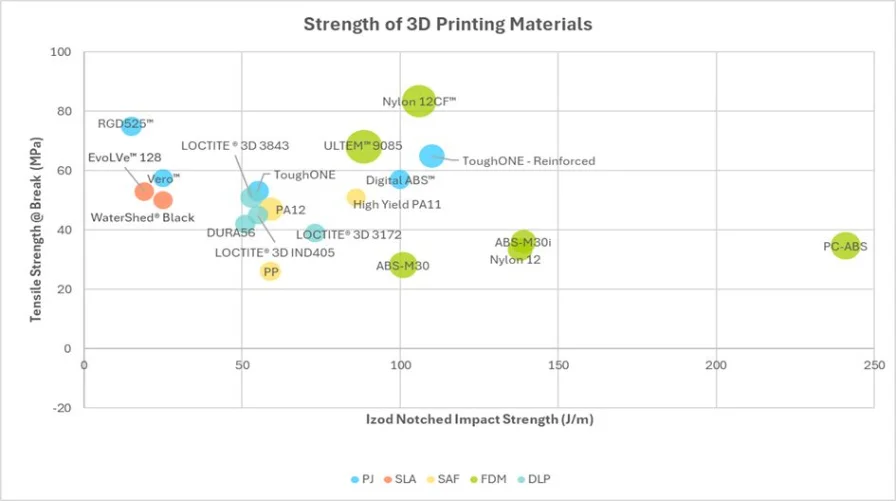

The chart above shows only a sample of the materials which Stratasys offers, which is a subset of all polymer 3D printing materials, which is of course a subset of materials in general.

This chart also only shows tensile strength, impact strength, and heat deflection temperature of these materials. There are several other ways to measure material strength and toughness.

Selecting the right polymer for functional prototyping or production requires more than just comparing tensile strength or heat resistance. Different applications call for different mechanical priorities, and knowing how to interpret these values is key.

In the sections below, we’ll define core performance metrics—like strength, stiffness, and toughness—and compare how they vary across 3D printing technologies. This will help you navigate the trade-offs and identify the best fit for your application.

Strength, stiffness, and toughness are all important characteristics of a durable material. But what do these terms actually mean? How do you pick which to prioritize when choosing a durable 3D printing material?

When you need durable parts, choose a 3D printing material based on the properties above to ensure the reliability and durability of your manufactured parts. Aside from material specifications, the underlying 3D printing technology should also have a significant bearing on your decision.

So, let’s take a look at strong 3D printing materials in each of the following categories:

When you think of “strong 3D printing materials,” FDM filaments are probably first to come to mind, which makes sense. Fused deposition modeling is known for some of the strongest 3D printing filaments around.

|

Material |

Notched Impact Strength (J/m) |

Elongation @ Break (%) |

Tensile Strength @ Break (MPa) |

Flexural Strength @ Break (MPa) |

HDT @ 264 psi (°C) |

|

PC-ABS |

241 |

4.7 |

34.7 |

(no break) |

112 |

|

ABS-M30i™ |

139 |

4 |

36 |

61 |

82 |

|

Nylon 12 |

138 |

30 |

33.4 |

(no break) |

75.3 |

|

Nylon 12CF |

106 |

2.4 |

83.5 |

153 |

154 |

|

ABS-M30™ |

101 |

8.1 |

28.1 |

(no break) |

99.9 |

|

ULTEM™ 9085 |

88.5 |

5.4 |

68.1 |

104 |

172.6 |

You might notice that there are clear tradeoffs here. If you want the most robust filament when it comes to being dropped, or general wear and tear, you might choose PC-ABS. If you need some amount of ductility, Nylon 12 looks better. If you require very high strength and temperature, ULTEM™ is likely best.

An engineering firm used Nylon 12CF, a carbon-fiber material, to manufacture a lightweight, high-strength support mount for maritime satellite antennae. The material's high tensile strength and rigidity, combined with the large build chamber of the F900 printer, made it an ideal choice for this application. The 3D printed antenna support mount decreased production cost by 20%, reduced the production time by 75%, and lowered the part’s weight by 38%.

Another thing to note when it comes to FDM: It is generally not isotropic. It is stronger within each layer than it is across the printed layers. For this reason, you can usually find two separate specifications, one for XZ strength and one for ZX strength. (The specs given above are for XZ direction. You can find datasheets with full specifications here.)

FDM technology is a classic example of a min-max approach. If you need to print something strong and/or large, it is often the best solution. On top of that, FDM machines are typically among the easiest to integrate and learn to use.

If appearance is critical, FDM technology might not be the best solution as it tends to leave visible layer lines on the printed part. FDM is also unsuitable for printing parts with several colors, materials, or very high-resolution delicate features.

PolyJet technology, historically, has been viewed as the total opposite side of the spectrum, when compared with FDM. If FDM is optimized for strength, PolyJet is favored for its aesthetics.

PolyJet can print multiple colors and materials in a single print. It boasts very high resolution (layer thickness down to 14 μm).

When it comes to toughness, however, PolyJet is not usually the first choice. This has changed somewhat with the recent release of the ToughONE material, however. ToughONE provides a unique combination of strength, toughness, and high surface finish. It can be used with color and multiple materials for functional prototyping and even production of final parts.

|

Material |

Notched Impact Strength (J/m) |

Elongation at Break (%) |

Tensile Strength (MPa) |

Flexural Strength (MPa) |

HDT @ 264 psi (°C) |

|

Vero® |

20-30 |

10-25 |

50-65 |

75-110 |

45-50 |

|

ToughONE™ |

90 |

47-58 |

48-53 |

77-87 |

59-62 |

|

ToughONE Reinforced |

90 |

22-36 |

61-63 |

85-87 |

75-77 |

|

Digital ABS™ |

90-110 |

25-40 |

55-60 |

65-75 |

51-55 |

|

RGD525™ |

14-16 |

10-15 |

70-80 |

110-130 |

55-57 |

PolyJet is ideal for applications where high precision, fine details, and a smooth surface finish are critical. It is particularly well-suited for:

SAF selective absorption fusion is a type of powder bed fusion (PBF) which also boasts some strong materials:

|

Material |

Notched Impact Strength (kJ/m2) |

Elongation at Break (%) |

Tensile Strength (MPa) |

Flexural Strength (MPa) |

HDT @ 264 psi (°C) |

|

Nylon PA12 |

4.17 |

11 |

47 |

54 |

77 |

|

High Yield PA11 |

7.4 |

30 |

51 |

51 |

47 |

|

Polypropylene |

3.5 |

22 |

26 |

28 |

56 |

Here, too, there’s a clear distinction between 3D materials that are very stiff (high flexural strength) and rugged (high impact). Resistance to temperature is an important factor here as well.

A manufacturing service bureau used SAF to produce parts for the aerospace industry, including manufacturing jigs, fixtures, tooling, and production parts. 3D composites preferred Nylon PA12, for its rigidity, feature resolution, and strength. SAF allowed for high-volume production with consistent quality, reducing cost per part and lead times, which enabled the company to meet tight production deadlines.

SAF is known for its high repeatability and low cost per part. Hundreds of parts can be printed in a single 12-hour print, enabling annual manufacturing volumes into the tens of thousands which, along with excellent strength specifications, makes it particularly suited for mid-to-high-volume production.

SAF is not recommended for applications which require a very smooth finish. In those cases, you may be better off choosing a PolyJet, SLA, or P3 DLP solution.

P3 DLP printers are known for their rare combination of excellent strength and material performance, along with exceptional surface finish and accuracy. This makes them perfect for production aids and other low-volume manufacturing, where the parts need to be strong enough to handle daily use, while also requiring a high level of surface finish and precision.

|

Material |

Impact Strength (J/m) |

Elongation at Break (%) |

Tensile Strength (MPa) |

HDT @ 66 psi (°C) |

|

LOCTITE® 3D 3172 |

73 |

105 |

39 |

51 |

|

LOCTITE 3D 3843™ |

53 |

43 |

51 |

63 |

|

LOCTITE 3D IND405™ |

51 |

101 |

45 |

53 |

|

DURA5™6 |

55 |

78 |

42 |

52 |

We can skip the “when to use” section here, as it works well in so many cases it’s actually simpler to just say when not to use it. There are essentially only two areas where P3 DLP underperforms:

Once you have a good idea which 3D printing technology will best suit your needs, you still have the task of selecting the right material for AM. You should consider the material’s various properties:

If you’re ever curious about possible material specs for your next project, I can give you two simple pieces of advice: