Manufacture production parts on-demand, without the high cost and long lead times of traditional machining and molding technologies.

3D printing requires no production tooling so you can bypass traditional time and cost constraints to quickly manufacture end-use products. Print parts on-demand and save on inventory and storage while avoiding the lead times associated with designing and creating production tooling. Whether you’re making aircraft parts or fashion accessories, 3D printing provides a scalable process for making custom and mid-volume production economically viable, and higher volume production more efficient than traditional processes.

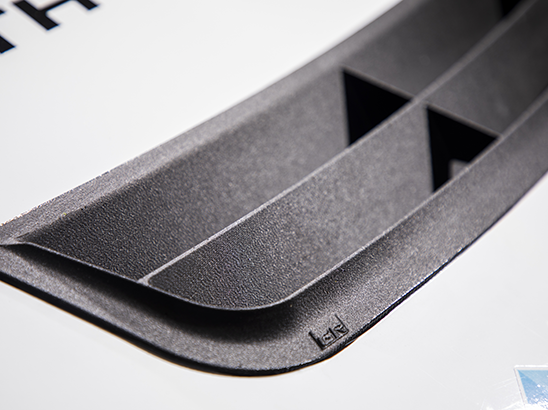

H350 powder bed technology offers the most cost-effective way to print production parts at scale.

Origin® Two brings industrial 3D printing to a completely new level with unparalleled accuracy, proven repeatability, very tight tolerances, and superb smooth surface finish.

FDM printers deliver industrial-grade printing with a highly versatile range of materials.

Simple but robust design, open materials and high reliability and uptime define Neo SL printers.

Print designs directly onto textiles and garments using the J850 TechStyle’s 3DFashion technology.

The traditional way to make things – machining and molding – has inherent constraints. As this solution guide shows, 3D printing with SAF powder bed technology offers an effective alternative.

Virtually any industry that manufactures products can benefit from the efficiencies of 3D printing.

Stratasys 3D printing solutions offer the materials and processes to satisfy regulatory requirements of the air and space industry.

3D printing is the perfect solution for highly customized parts and viable low to mid-volume production.

Develop and deliver your products faster by leveraging 3D printing’s ability to make the production cycle more agile.

Stratasys 3D printing solutions offer the materials and processes to satisfy regulatory requirements of the air and space industry.

3D printing is the perfect solution for highly customized parts and viable low to mid-volume production.

Develop and deliver your products faster by leveraging 3D printing’s ability to make the production cycle more agile.

Fuse art, expression and technology with Stratasys Direct-to-Textile 3D fashion technology.

Tim Ganley – Go Orthotics Managing Director

Customer Success StoryWhen a production change forced the redesign of a truck camera mount, 3D printing made it possible to still meet the schedule.

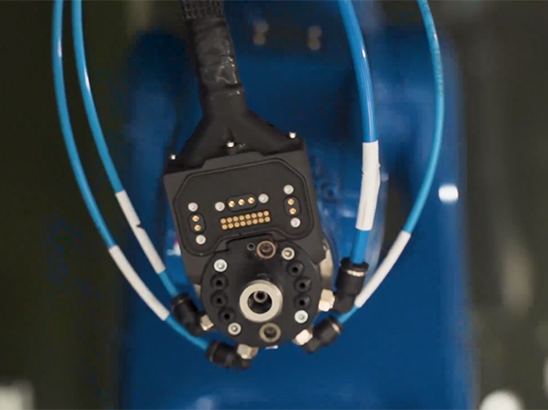

The lack of an off-the-shelf part solution for its production robots led Rivelin Robotics to 3D print its own parts.

When a production change forced the redesign of a truck camera mount, 3D printing made it possible to still meet the schedule.

The lack of an off-the-shelf part solution for its production robots led Rivelin Robotics to 3D print its own parts.

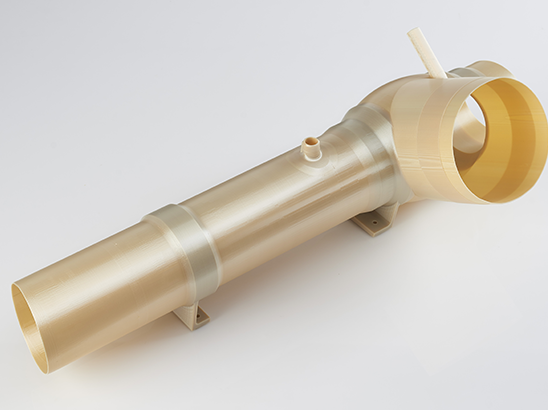

Lockheed Martin took advantage of FDM material technology to streamline the production of unique Orion space capsule parts.