FDM’s additive nature and soluble support material simplify the creation of parts with complex geometries and internal cavities. FDM technology is clean and office-friendly, thanks to production grade materials that are mechanically and environmentally stable. FDM thermoplastics also deliver the necessary properties for applications that demand precise tolerances, durability, and stability in different environments. They include many of the same thermoplastics used in traditional manufacturing processes like injection molding.

Stratasys FDM technology offers valuable efficiencies over conventional manufacturing methods, letting you cut production costs while benefitting from shorter lead times for quicker market entry. FDM’s broad material portfolio addresses a wide spectrum of applications, from functional prototyping to end-use parts.

FDM technology is trusted for its precision, reliability and repeatability. With printers that are at home in an office, to industrial-grade platforms for the factory floor, it is one of the easiest 3D printing technologies to learn and operate. Material diversity opens your application space with capabilities bridging engineering-grade plastics to high-performance polymers.

The versatility, ease of use and sizeable material selection of FDM technology makes it a go-to resource for all major industries that need time and cost-efficient alternatives to traditional manufacturing.

FDM parts help aerospace companies reduce weight and increase efficiency.

Strong carbon-fiber FDM materials give auto manufacturers options for ergonomic, agile tooling.

The combination of capable printers, durable materials and proven reliability makes FDM technology the perfect fit for many different applications.

Durable FDM materials offer a faster, more economical way to make essential manufacturing aids.

Ease of use and durable print results make functional prototyping a foundational FDM application.

High-performance FDM polymers offer a faster alternative to conventionally made composite tooling.

FDM printers cross the spectrum from small but capable office-friendly systems to large-capacity industrial printers.

A significant advantage of FDM technology is the quantity of available materials. They include durable engineering-grade thermoplastics for high-use, general purpose printing, strong carbon fiber materials, and high-performance polymers capable of meeting the most demanding applications.

This PEI polymer offers excellent physical and mechanical properties for demanding applications.

9085, 1010 and ULTEM™ are trademarks of SABIC, its affiliates or subsidiaries.

This PEKK-based material has low outgassing characteristics in addition to superior mechanical properties.

Nylon 12CF contains chopped carbon fiber, making it one of the stiffest materials in the FDM suite of thermoplastics.

The addition of chopped carbon fibers to ABS provides a stronger, stiffer version of this versatile thermoplastic.

Simplify your 3D printing workflow with powerful and intuitive software.

GrabCAD Print software is what makes Stratasys 3D printers go, providing the features and flexibility to make 3D printing easy and understandable. At its core, GrabCAD Print software removes the friction of going from a CAD model to a physical 3D printed part and speeds up the process. You designed the part, now let GrabCAD Print software do the rest to make it a reality.

FDM Technology revolutionizes industries by providing scalable additive manufacturing solutions. From aerospace to healthcare, FDM helps companies increase efficiency and improve product design.

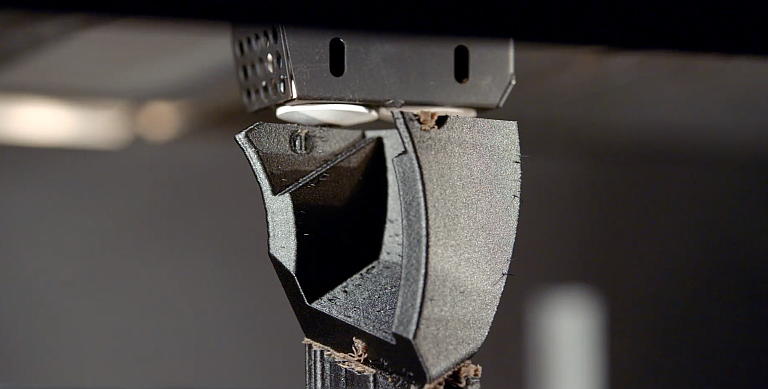

Gosiger Manufacturing 3D printed a high-performance turret-mounted catcher with Stratasys composite 3D printer and materials. Download the use case today!

View moreIf you want to learn how East/ West Industries used Stratasys technology to produce its metal forming dies 87% faster, read our use case now.

View moreLearn how Caterpillar, manufacturing leader in construction and mining equipment, utilizes Stratasys FDM technology to reduce cost and expedite lead times.

View moreFDM Technology revolutionizes industries by providing scalable additive manufacturing solutions. From aerospace to healthcare, FDM helps companies increase efficiency and improve product design.

Gosiger Manufacturing 3D printed a high-performance turret-mounted catcher with Stratasys composite 3D printer and materials. Download the use case today!

If you want to learn how East/ West Industries used Stratasys technology to produce its metal forming dies 87% faster, read our use case now.

Learn how Caterpillar, manufacturing leader in construction and mining equipment, utilizes Stratasys FDM technology to reduce cost and expedite lead times.